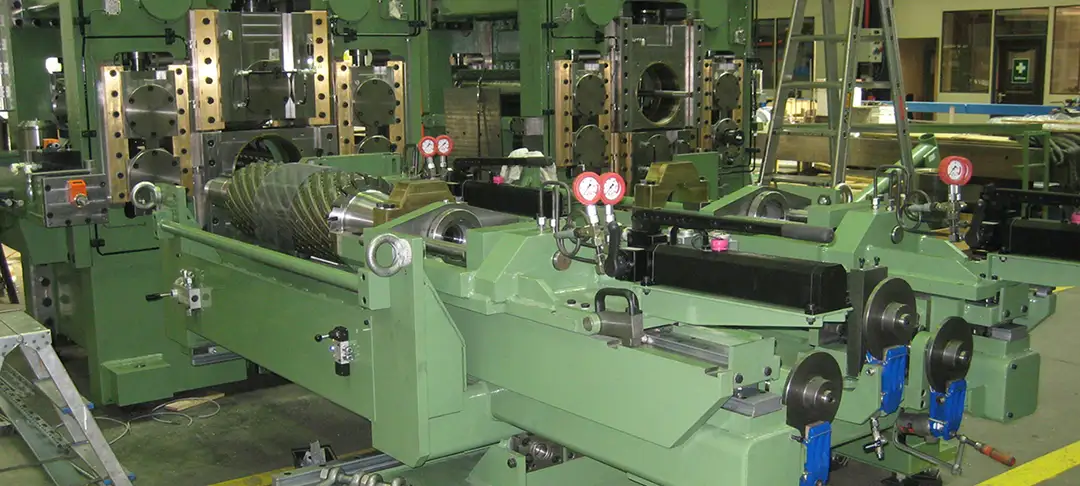

Fräsmaschinen für Kupferband

Entfernung der Oberflächenoxidation von gegossenem oder warmgewalztem Kupferband.

Entfernung der Oberflächenoxidation von gegossenem oder warmgewalztem Kupferband. Eine Schicht von 0,2 mm bis 0,5 mm wird von der Ober- und Unterseite des Bandes entfernt, sodass das Material mit verbesserter Ebenheit und hervorragender Oberflächengüte dem nachgelagerten Kaltwalzprozess zugeführt werden kann.

Highlights

- Solide und vibrationsarme Maschinenkonstruktion

- Hochwertige Schneidwerkzeuge (HSS oder Wolframkarbid)

- Hydraulischer Abgleich der Einbaustücke für Fräser und Gegendruckwalze

- Banddicken- und Bandbreitenbestimmung, für automatische Frässpaltverstellung

- Einstellbare Materialdurchlaufgeschwindigkeiten und Fräserschnittgeschwindigkeiten für optimale Bandoberfläche und Fräserstandzeit

- Mahlspaltschmierung durch Emulsionssprühsystem

- Effizientes Späneabsaugsystem

OPTIONALE FUNKTIONEN

- Kantenfräsmaschine

- Spänepresse

- Schleifmaschine